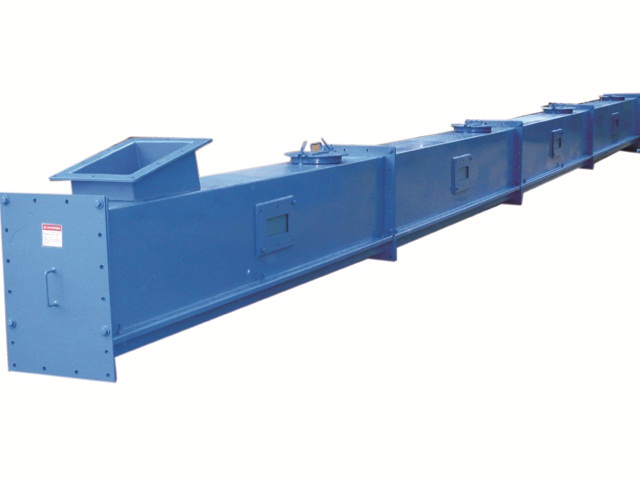

Air Slides

The HYQUIP air slide conveyors efficiently combine low air pressure and gravity to fluidize and convey most types of fine dry granular materials regardless of abrasive nature or bulk density. The only criteria is particle size and moisture.

The low profile design is totally enclosed and dust free, making it perfect for conveying from silos, rail cars and multiple discharge points or feeding to weigh hoppers, even over long distances.

The energy efficiency and ease of installation of the HYQUIP air slide conveyors contribute to a cost effective solution for conveying very fine, dusty or granular materials. And because there are no moving parts in the material flow to wear out, very little maintenance is required.

Air slide conveyors can be used in a single straight run, but are equally as effective when used in large systems. Through the use of turn boxes, conveyors can easily change directions, merge, or split without the need for powered conveyors or diverters. Manual or powered shut off gates can be integrated into any point of the system to control flow.

The maximum range of the conveyors are limited only by the height of the source. Conveyors require a minimum of a 5 degree drop angle to function properly. A 10 degree angle is recommended for most applications.